जब आधुनिक प्रिंटिंग प्रौद्योगिकियों की बात आती है, तो दो शब्दों को बहुत ध्यान में रखा जाता है: डीटीएफ और यूवीडीटीएफ। फिलहाल वे मिल कर सुनने में मिल सकते हैं, लेकिन वे अलग-अलग प्रिंटिंग तकनीकों को संदर्भित करते हैं जो अलग-अलग उद्देश्यों की ख़ातिर काम करते हैं। यह लेख डीटीएफ और यूवीडीटीएफ के बारे में, उनकी विशेषताओं और उनके बीच अंतर का अन्वेषण करता है।

डीटीएफ क्या है?

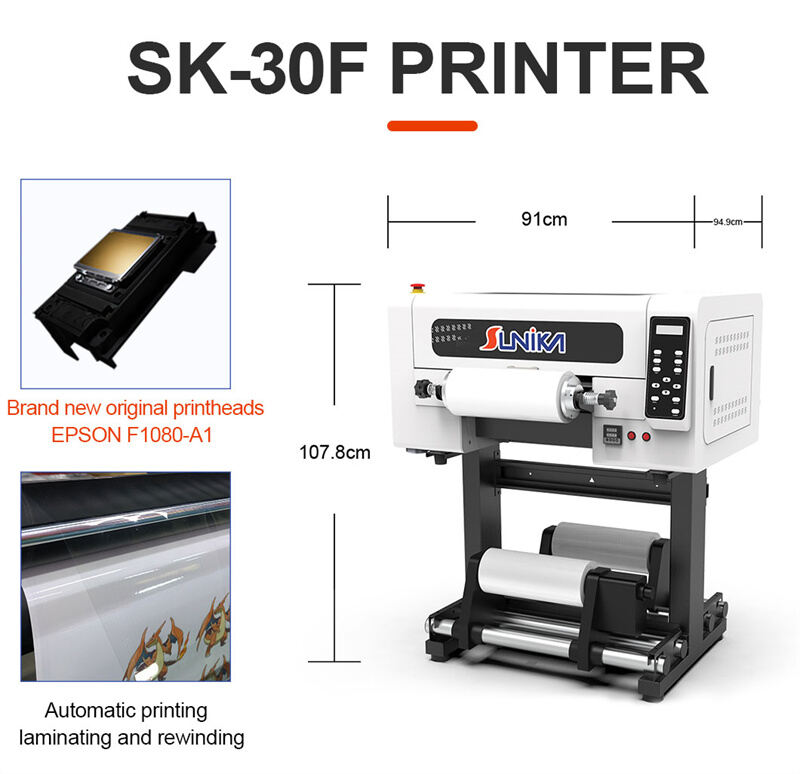

डीटीएफ का मतलब है डायरेक्ट-टू-फिल्म प्रिंटिंग। नाम से ही पता चलता है, इस प्रक्रिया में एक डिजाइन को पहले फिल्म पर प्रिंट किया जाता है, फिर इसे अभीष्ट सतह पर स्थानांतरित किया जाता है, अक्सर कपड़ों जैसे टी-शर्ट, हूडियों या बैग्स पर। डीटीएफ की लोकप्रियता बढ़ी है क्योंकि यह अपनी बहुमुखीता और विभिन्न प्रकार के कपड़ों, जिनमें कॉटन, पोलीएस्टर, मिश्रण और भी गहरे रंग के सामग्री पर बहुत उज्ज्वल और उच्च गुणवत्ता के प्रिंट उत्पन्न करने की क्षमता के कारण है।

डीटीएफ प्रिंटिंग की मुख्य विशेषताएँ:

1. व्यापक सामग्री संpatibleता: परंपरागत विधियों जैसे DTG (Direct-to-Garment) के विपरीत, DTF अधिक विस्तार से तेल-जैसी सामग्रियों पर काम करती है।

2. स्थायी प्रिंट: परिणामी डिज़ाइन सुप्लिक्स, धोने योग्य और स्थायी होते हैं, जिन्हें वस्त्र के लिए आदर्श माना जाता है।

3. लागत-प्रभावी: कम सेटअप लागत और प्रीट्रीटमेंट (कुछ अन्य विधियों में आवश्यक) की आवश्यकता के बिना, DTF विशेष रूप से छोटे व्यवसायों और कस्टम प्रिंट दुकानों के लिए अधिक सस्ता है।

4. चमकीले रंग: DTF पूर्ण-रंग प्रिंट की अनुमति देता है, जिसमें जटिल विवरण और ग्रेडिएंट भी शामिल हैं।

UVDTF क्या है?

दूसरी ओर, UVDTF का मतलब UV Direct-to-Film प्रिंटिंग होता है। यह तकनीक UV प्रिंटिंग प्रौद्योगिकी को direct-to-film प्रक्रिया के साथ जोड़ती है। UV प्रिंटिंग में प्रिंटिंग के दौरान अक्षरत: रंगों को सख्त करने या ठहराने के लिए अपवर्तित प्रकाश (UV) का उपयोग किया जाता है। यह अधिकांशतः कपड़े के अलावा अनुप्रयोगों के लिए इस्तेमाल किया जाता है, जैसे कि कांच, धातु, केरामिक, लकड़ी और अन्य कठोर सतहें, जिससे UVDTF कस्टम फोन केस, प्रचार सामग्री, साइन या लेबल जैसे उत्पादों के लिए आदर्श होता है।

UVDTF प्रिंटिंग के मुख्य विशेषताएँ:

1. निखारे विवरण और सहनशीलता: UV-सेतुकृत प्रिंटिंग को उन्हें निखारे विवरण और चमकीले रंग उत्पन्न करने के लिए जाना जाता है। सेतुकरण प्रक्रिया डिज़ाइनों को अत्यधिक सहनशील बनाती है।

2. कठोर सतहों के लिए उपयुक्त: जबकि DTF आमतौर पर कपड़ों के लिए इस्तेमाल किया जाता है, UVDTF गैर-पोरस सामग्रियों पर उत्कृष्ट होता है, जिससे फैशन के परे क्षेत्रों में विशिष्ट अनुप्रयोग होते हैं।

3. तत्काल सेतुकरण: UV प्रकाश तत्काल रंग को सेतुकृत करता है, जिससे प्रक्रिया तेज़ हो जाती है और उत्पादों को प्रिंटिंग के बाद तुरंत उपयोग या बिक्री के लिए तैयार हो जाते हैं।

4. उच्च स्तर का आकर्षण: UVDTF प्रिंटिंग एक प्रीमियम फिनिश प्रदान करती है, जिसे ग्लास आर्टवर्क, ब्रँडेड पैकेजिंग या क्रिस्टल-स्पष्ट स्टिकर्स जैसे उच्च-स्तरीय उत्पादों को बनाने के लिए इस्तेमाल किया जा सकता है।

DTF और UVDTF के बीच अंतर

अब हमने दोनों प्रौद्योगिकियों का अध्ययन किया है, चलिए मुख्य अंतरों को प्रकाशित करते हैं:

सामग्री संगतता:

1. DTF मुख्य रूप से कपड़े-आधारित अनुप्रयोगों के लिए है, जैसे कपड़े और टेक्साइल्स।

2. UVDTF गैर-कपड़ा आइटम्स के लिए आदर्श है, जो मजबूत सतहों जैसे कांच, प्लास्टिक या धातु पर केंद्रित है।

प्रिंटिंग प्रक्रिया:

1. DTF एक हीट ट्रांसफर मेथड का उपयोग करता है, जहाँ डिज़ाइन्स पहले फिल्म पर प्रिंट किए जाते हैं और फिर स्टिकी गुम के साथ कपड़ों पर स्थानांतरित किए जाते हैं।

2. UVDTF यूवी प्रकाश का उपयोग करता है जो तत्काल इंक को ठस जाने के लिए काम करता है, फिल्म या सतह पर सीधे स्थायी प्रिंट बनाता है।

लागत और सेटअप:

1. DTF अधिक कॉस्ट-इफ़ैक्टिव और शुरुआती-दोस्ताना है, विशेष रूप से छोटे प्रिंट चलने या कस्टम एपरेल व्यवसायों के लिए उपयुक्त है।

2. UVDTF, अधिक उन्नत और उपकरण-भारी होने के कारण, आमतौर पर अधिक शुरुआती लागत होती है और इसे बड़े पैमाने पर या हाई-एंड प्रोडक्ट कस्टमाइज़ेशन के लिए अधिक उपयुक्त माना जाता है।

पूर्णता और सहेजगी:

1. DTF कपड़ों और तारे के लिए फ्लेक्सिबिलिटी और सहेजगी प्रदान करता है, जिससे कपड़े पर मुलायम महसूस होता है।

2. UVDTF, अपने UV क्यूरिंग के साथ, कड़ा और सहेजगी पूर्वक पूरा होता है, जो उच्च स्तर की विवरण और मजबूती की आवश्यकता होने पर अधिक मूल्यवान वस्तुओं के लिए इdeal है।

Dtf एप्लिकेशन

UV DTF एप्लिकेशन

DTF और UVDTF के बीच चुनाव

DTF और UVDTF के बीच चुनाव अंततः आपके द्वारा प्रिंट करने की बात पर और आपके द्वारा चलाए जा रहे व्यवसाय के प्रकार पर निर्भर करता है।

• यदि आपका ध्यान समूहिक कपड़ों, टी-शर्ट या अन्य तंतु-आधारित उत्पादों पर है, तो DTF सबसे अच्छा विकल्प है। यह फैशन उद्योग और छोटे व्यवसायों के लिए लागत-कुशल, स्थायी और लचीला समाधान है।

• यदि आप ग्लासवेयर, प्लास्टिक या धातु के प्रचार उत्पादों जैसी अन्य तंतु-आधारित वस्तुओं को ब्रँडिंग या संवर्द्धित करने के व्यवसाय में हैं, तो UVDTF अन्य प्रिंटिंग विधियों की तुलना में अनुपम विवरण और स्थायित्व का स्तर प्रदान करता है। यह कठोर सतहों पर उच्च गुणवत्ता और चमकीले फिनिश की आवश्यकता वाले उद्योगों के लिए इdeal है।

अंतिम विचार

जैसे-जैसे कस्टम प्रिंटिंग की मांग बढ़ती जा रही है, दोनों DTF और UVDTF उन कारोबारों के लिए उत्साहवर्धक संभावनाएं पेश करते हैं जो अपनी उत्पादन श्रृंखला को विस्तारित करना चाहते हैं। चाहे आप फैब्रिक पर प्रिंट कर रहे हों या कठोर सतहों पर, इन तकनीकों के बीच अंतर समझने से आपको अपने लक्ष्यों के अनुरूप निर्णय लेने में मदद मिलेगी।

उपयुक्त विधि का चयन—फैब्रिक के लिए DTF या कठोर सतहों के लिए UVDTF—आपको अपने ग्राहकों को विभिन्न बाजारों में विशेष रहने वाले उच्च गुणवत्ता और स्थायी उत्पादों की व्यापक श्रृंखला पेश करने में सक्षम बनाएगा।

हॉट न्यूज

हॉट न्यूज2025-09-30

2025-09-18

2025-07-26

2025-07-08

2025-07-03

2025-07-01

साइट कॉपीराइट © झेंगचू न्यू सेंचुरी डिजिटल टेक्नोलॉजी कंपनी लिमिटेड। सभी हक मحفوظ हैं - गोपनीयता नीति-ब्लॉग